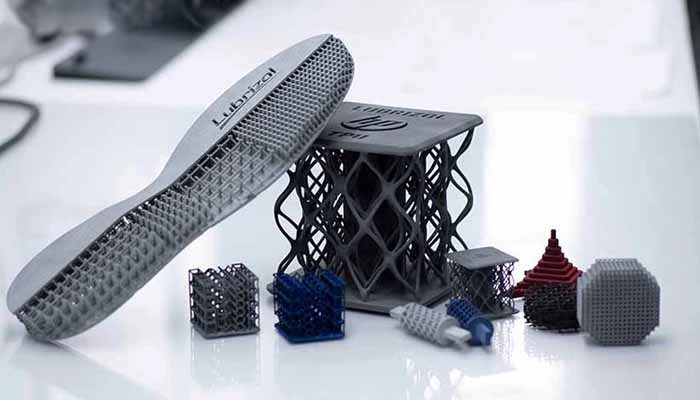

Materials

When it comes to 3D printing, the choice of materials is crucial in determining the final outcome of the printed object. Various materials are used in the process, each with its own unique properties and characteristics.

From traditional PLA and ABS to cutting edge materials like carbon fiber-infused filament and flexible TPU, this page provides insight into some of the different materials.

Here are just a few of the types of filament available for FDM printing. Glass fiber, metal, wood filled, magnetic, conductive, and ASA are a few more filaments that can be used.

With most filaments there are lots of variations available in terms of colour, finishes, transparent and many more.

PLA

PLA or polylactic acid is the most used filament due to it being easy to print with good results.

PLA Properties:

Strength: Medium | Flexibility: Low | Durability: Medium

Difficulty to use: Low

Print temperature: 180 – 230 °C

Print bed temperature: 20 – 70 °C (but not needed)

Shrinkage/warping: Minimal

Soluble: No

Food safety: Refer to manufacturer guidelines

Applications: Models, trinkets, toys, food packaging etc.

More Information:

PLA is the easiest filament to print due to requiring lower temperatures to print with and less warping from the print bed, meaning that a heated bed isn’t required although it helps. Another benefit of using PLA is that it doesn’t emit nasty odors like ABS does.

Another reason for PLA’s popularity in the 3D print world is the abundance of colours and styles.

PLA is brittle compared to other filaments on the market, so it should be avoided when parts are going be subject to being twisted, bent or repeatedly dropped. PLA is also the lowest rated in temperature resistance, deformation can start with temperatures around 50-60°C.

Recap:

Pros: Easy to print, wide variety of colors and styles, “biodegradable”

Cons: Brittle, lackluster mechanical properties

ABS

Acrylonitrile butadiene styrene, more commonly known as ABS, is less popular than PLA for everyday printing. This is due to being a harder material to print due to needing higher temperatures required in the nozzle, chamber and the print bed, this is because ABS is prone to warping and shrinking without a heated bed.

ABS is commonly used in injection molding and common household items such as Lego and bicycle helmets.

Properties:

Strength: High | Flexibility: Medium | Durability: High

Difficulty to use: Medium

Print temperature: 210 – 250 °C

Print bed temperature: 80 – 110 °C

Shrinkage/warping: Considerable

Soluble: In esters, ketones, and acetone

Food safety: Not food safe

Applications: Prototyping, industrial, outdoor parts, automotive parts, etc.

More Information:

Components made from ABS have higher durability and temperature resistance, but tend to warp or shrink when cooling, ABS also emits hazardous fumes when printing.

ABS is a tough and strong filament and can withstand high stress and temperatures while still being moderately flexible. ABS is a great option for parts that will/could be subject to being repeatedly dropped, handled a lot and will have to withstand heat.

Recap:

Pros: High strength, high durability, resistance to high temperatures

Cons: Warps easily, hazardous fumes, requires a high-temperature print nozzle

PTEG

PETG or polyethene terephthalate is one the most commonly used plastics across the globe, best known for producing water bottles, food containers and is even found in clothing.

Properties:

Strength: High | Flexibility: Medium | Durability: High

Difficulty to use: Low

Print temperature: 220 – 250 °C

Print bed temperature: 50 – 75 °C

Shrinkage/warping: Minimal

Soluble: No

Food safety: Refer to manufacturer guidelines

Applications: Remote controlled toy parts, planters, functional parts, food packaging etc.

More Information:

PETG is a naturally clearer material, less brittle and easier to print with than ABS. With that in mind PTEG is considered the middle ground between PLA and ABS.

PTEG is a good all-rounder material and stands out from others due to its strength, flexibility and temperature and impact resistance. This makes PTEG an ideal filament for functional parts that could experience sudden stress such as mechanical parts and protective components.

Recap:

Pros: Flexible, durable, easy to print

Cons: Susceptible to moisture, surface scratches easily

TPE/TPU

Thermoplastic elastomers are essentially plastics with rubber like qualities, making them very flexible and durable.

Properties:

Strength: Medium | Flexibility: Very High | Durability: Very High

Difficulty to use: Medium (TPE, TPC); Low (TPU)

Print temperature: 210 – 230 °C

Print bed temperature: 30 – 60 °C (but not needed)

Shrinkage/warping: Minimal

Soluble: No

Food safety: Not food safe

Applications: Protective packaging, anti vibration parts, seals and gaskets etc.

More Information:

With TPE being soft and stretchable, this material can withstand physical punishment that neither PLA nor ABS can tolerate. But printing TPE is not always easy, it can be a very difficult material to extrude.

TPU is a variety of TPE that is more commonly used in the 3D printing world. Compared to TPE, TPU is a bit more rigid making it easier to print and a more durable material.

Recap:

Pros: Extremely flexible, perfect for parts that bend or compress

Cons: Difficult to print, requires tight filament path and slow print speed

Nylon

Polyamide or PA is part of the synthetic polymer's family used in many industrial applications. As a filament has expectational strength, durability and flexibility.

Properties:

Strength: Very High | Flexibility: High | Durability: High

Difficulty to use: Medium

Print temperature: 240 – 260 °C

Print bed temperature: 70 – 100 °C

Shrinkage/warping: Considerable

Soluble: No

Food safety: Refer to manufacturer guidelines

Applications: High-performance machine parts, automotive, hinges, industrial

More Information:

With nylon's high strength and durability properties, it makes nylon the perfect material to create tools, mechanical parts, or functional prototypes.

Recap:

Pros: High strength, high flexibility, high durability

Cons: Typically expensive, susceptible to moisture, requires high nozzle and print bed temperature

PC (Polycarbonate)

PC is one of the strongest filaments on the market for 3D printing along with being extremely durable and resistant to heat being able to withstand temperatures up to 110°C, and both physical and impact.

Properties:

Strength: Very High | Flexibility: Medium | Durability: Very High

Difficulty to use: Medium

Print temperature: 270 – 310 °C

Print bed temperature: 90 – 110 °C

Shrinkage/warping: Considerable

Soluble: No

Food safety: Not food safe

Applications: Lighting, electrical and electronic equipment, etc.

More Information:

Because of the properties of polycarbonate, it makes it an ideal filament for parts that need to retain strength, toughness and their original shape when exposed to high temperatures such as electrical, mechanical or automotive parts.

Recap:

Pros: Extremely strong, resistant to heat and physical impact

Cons: Susceptible to moisture, requires very high print temperature

Carbon Fiber

Carbon fiber is used in the added to the above filaments to reinforce the material and change the properties of the filaments. As a result, this creates an extremely stiff and rigid material with little weight, meaning filaments reinforced with carbon fiber can withstand a wide variety of end use applications.

Thanks to its structural strength, filaments reinforced with carbon fiber make it the perfect choice for parts that require high mechanical properties.

Recap:

Pros: Strong and lightweight material, ideal for functional applications

Cons: Causes wear and tear on 3D printer nozzle